|

Great progress has been made recently in the

development of stormwater filtration technology. The following

technologies will be utilized as needed in restoration efforts. Numerous

additional proprietary and natural water filtration technologies will be

also be employed, reflecting American ingenuity at its best.

Natural Pollution

Filtration Systems

The original

wetlands along the St Johns consisted of an extensive tree canopy as

well as plentiful shrubs plants and grasses. These wetlands began to

disappear as waterfront homes and businesses were built in the river

basin. These natural filtration systems (which act like our kidneys) in

removing pollutants and impurities are vital to the health of the river.

A concerted effort to reestablish an extensive tree canopy, shrubs and

grasses and other natural systems will be a major component in the

restoration plan.

|

|

Green Roof Systems capture and hold stormwater thereby reducing runoff. Green

Roofs also reduce HVAC costs, dramatically extend the life of the

roof (50-60 years) and provide numerous additional benefits.

Stormwater Capture and Reuse

Systems

Capture & Reuse Tanks

–

large, underground or surface containers designed to hold large

volumes of water. Cisterns may be comprised

of steel,

plastic, fiberglass, concrete, brick or other materials.

Smaller Rain

Barrels are commercially available as well and serve to

reduce the volume of stormwater that leaves individual residential

properties.

Proprietary

Stormwater Infiltration Systems

When an area is developed, buildings

and parking areas overcome the natural absorption area where the

rain would normally be infiltrated back into the ground. These

impervious structures offset the typical absorption pattern. As a

result, when the rain is not allowed to penetrate it begins to

build up, may cause ponding or

flooding and/or begins to flow to another location.

By using infiltration chambers,

rainwater is collected in inlet structures and piped to an

underground retention/detention system. Infiltration chambers may

be used as underground retention/detention systems, as

replacements for ponds, concrete structures or pipe and stone

installations. This technology provides a complete stormwater

management plan consisting of filtration, conveyance, storage and

infiltration.

Porous

Pavers/Pavement - pavement systems are constructed from

interlocking, high strength blocks made from bricks, concrete

chambers or recycled plastic that prevent soil compaction and

provide load support. Chambers can then filled with soil and

seeded, or sodded.

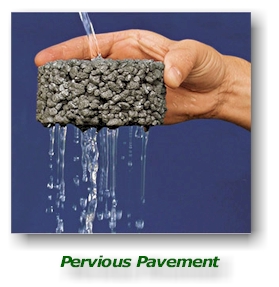

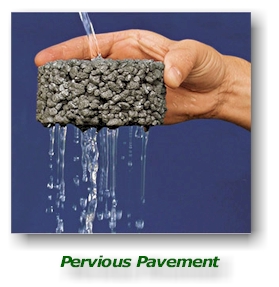

Pervious Pavement

- a

permeable pavement surface with an underlying stone reservoir that

temporarily stores surface runoff before infiltrating into the

subsoil. This porous surface replaces traditional pavement,

allowing parking lot runoff to infiltrate directly into the soil

and receive water quality treatment.

Proprietary

Pollution Filtration Systems

There are numerous

leading edge proprietary pollution filtration technologies that will be

an integral part of the restoration effort. The following are a few of

the products, known in scientific circles as Structural BMPs (Best

Management Practices). The majority of these products are designed to

filter and capture pollutants in stormwater runoff. Software that is

designed to develop restoration strategies, track and quantify the

removal of individual pollutants will be employed as well.

|

|

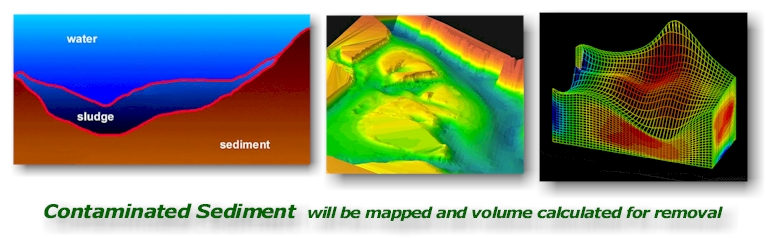

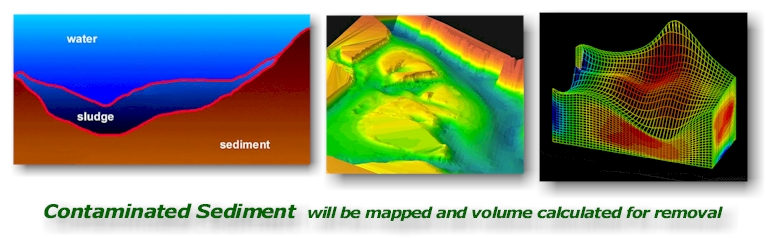

The St Johns and its tributaries suffer with a vast layer of

contaminated sediment that coats the bottom of these rivers. This

toxic mixture of silt, sand and muck contains numerous poisons that

continue to kill the river’s aquatic ecosystem. This layer of

“sludge” has accumulated after many years of stormwater runoff

washing in the dirt, chemicals, oil, trash and debris from the

roofs, roads and parking lots. Industrial pollutants and inefficient

and malfunctioning wastewater treatment plants also add to the

contaminants that damage the river.

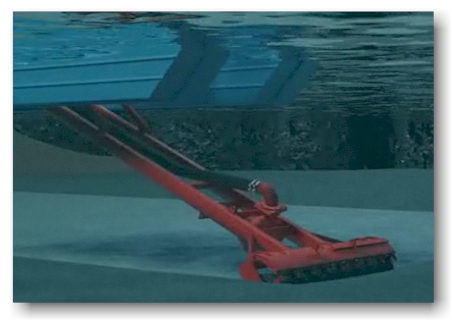

The restoration of the river will require that this contaminated

sediment be REMOVED.

A

major component of the restoration program will be to incorporate a

NEW, cost effective contaminated sediment removal process. This new

process design will incorporate a creative system of sediment

removal, filtration, dewatering and air drying the sediment through A

major component of the restoration program will be to incorporate a

NEW, cost effective contaminated sediment removal process. This new

process design will incorporate a creative system of sediment

removal, filtration, dewatering and air drying the sediment through exposure to sunlight. The contaminated sediment will be removed from

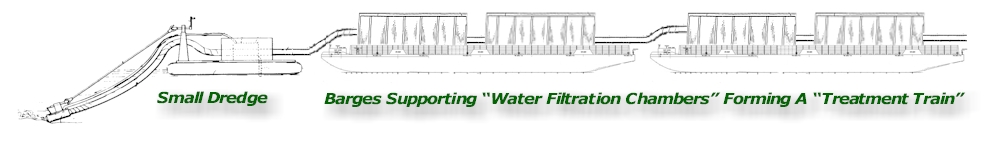

the stream bottom utilizing a small dredge that will allow access to

the narrow and shallow upper reaches of the tributary.

exposure to sunlight. The contaminated sediment will be removed from

the stream bottom utilizing a small dredge that will allow access to

the narrow and shallow upper reaches of the tributary.

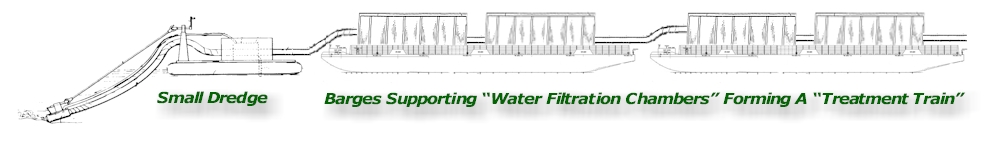

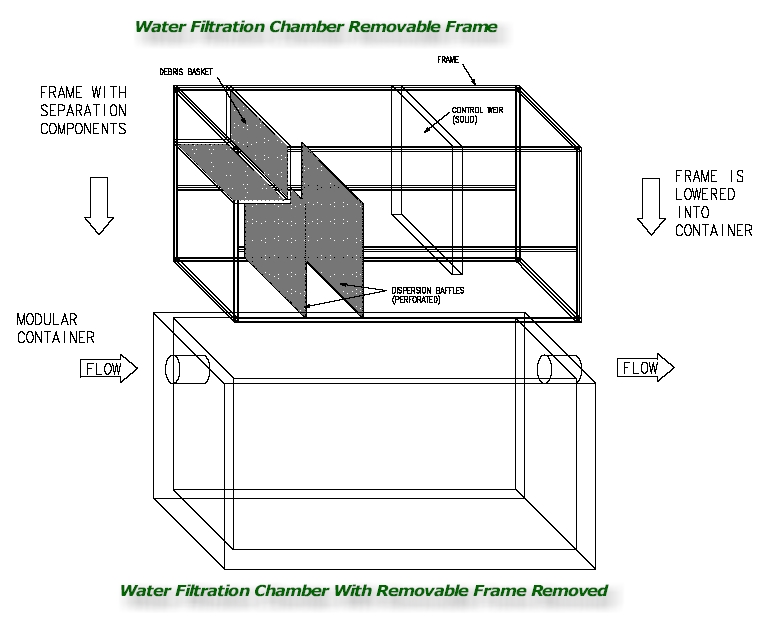

As

the sediment is "vacuumed" from the bottom of the stream and shallow

wetlands, the liquid slurry will be directed to a series of floating

filtration chambers that are mounted on nearby compact floating

barges. The filtration chambers utilize patented

CrystalStream Technologies™

water

quality filtration technology that has been successfully deployed

over the past ten years to filter stormwater discharges.

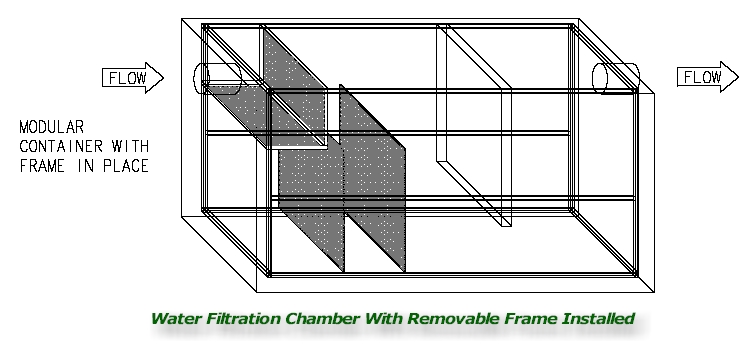

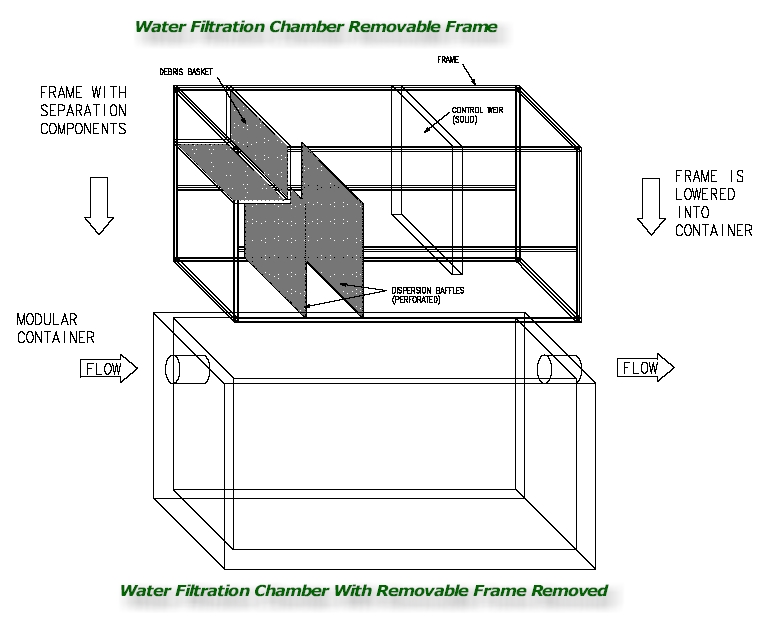

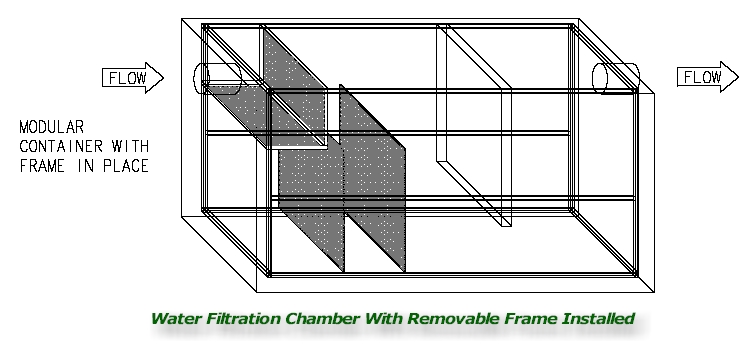

A new modular water filtration

system has been designed to efficiently dewater contaminated

sediment. This new system will remove, capture, segregate and

dewater sand, debris and progressively smaller contaminated sediment

particles.

This process is covered by one or more of the following US.

Patents: 6,797,161; 6,936,163; 6,939,461; 6,951,607; 6,994,783;

7,011,743; 7,037,436

The dredged water stream will be filtered as the slurry flows

through a progression of filtration chambers that are piped

together. The clean water at the end of this "treatment train" can

then be returned to the river thereby providing substantial savings

in transporting wet sludge to a landfill. Some of the captured sand

can be air dried and disinfected by exposing the chambers to

sunlight while floating them on "drying barges." This sand can then

be reintroduced along the shores and wetlands to plant new native

submerged aquatic vegetation (SAV).

Chambers that are located farther back in the "treatment train" will

capture smaller particles containing high levels of organic matter.

After this sediment has been dewatered and tested to ensure purity,

it may serve as a fuel supplement to be burned in power boilers to

generate electricity. The remaining dried sediment can be thermally

treated, trucked to

a nearby landfill or used as a soil amendment for land application.

Some of the sand could possibly be sold to make cement/concrete as

well.

The modular water filtration chambers will be designed to be

light-weight, rugged with the ability to stack vertically. A shore

mounted small hoist/crane will "pick" the chambers from the "drying

barges." The chambers will be loaded and transported by a light duty

roll-off transport trucks.

|

This process is covered by one or more of the following US.

Patents: 6,797,161; 6,936,163; 6,939,461; 6,951,607; 6,994,783;

7,011,743; 7,037,436

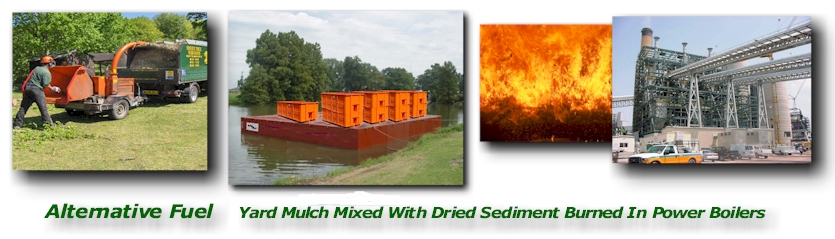

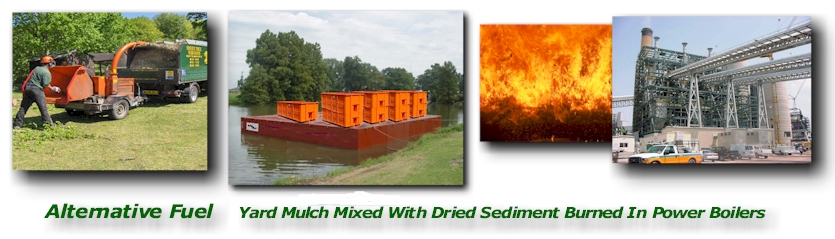

Alternative Fuel

Chambers that are located farther back in the "treatment train" will

capture smaller particles containing high levels of organic matter.

After this sediment has been dewatered and tested to ensure purity, it

may serve as a fuel supplement to be burned in power boilers to generate

electricity.

Thermal Treatment Technology

The remaining dried contaminated sediment can be thermally treated

or trucked to a nearby landfill. Thermally treated sand might be used as a soil amendment for land application.

Some of the sand could possibly be sold to make cement/concrete as

well.

|

A

major component of the restoration program will be to incorporate a

NEW, cost effective contaminated sediment removal process. This new

process design will incorporate a creative system of sediment

removal, filtration, dewatering and air drying the sediment through

A

major component of the restoration program will be to incorporate a

NEW, cost effective contaminated sediment removal process. This new

process design will incorporate a creative system of sediment

removal, filtration, dewatering and air drying the sediment through